Your partner in plastic extrusion

specialize in plastic extrusion to create high-quality products that meet the needs of our customers

In the world

of extrusion

since 1967

Our History

Borsato Profili is proud to celebrate its first 56 years of business in the new plant of Maerne di Martellago (Italy).

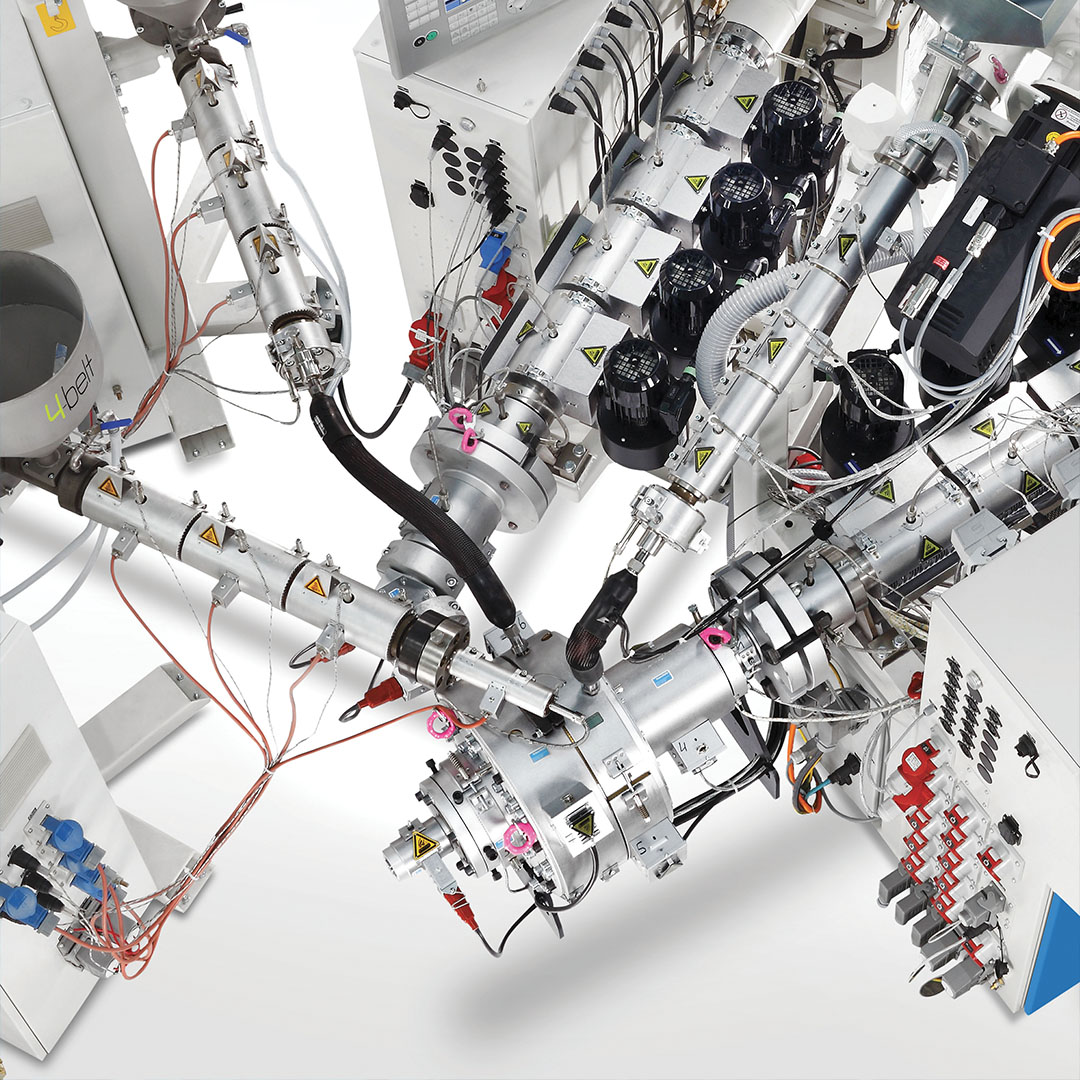

The new structure has made possible important technological developments over these years, in the sector of thermoplastic profiles extrusion.

That is because our operating structures, our systems, our machinery and our equipments are the maximum in technology and high performance currently available on the market.

The idea and the project

Services

We can guide our clients through every step of the process of study, design and equipment for production (dies and calibrators), construction of the equipment, its use on our production lines and finishing of the product with additional processing (application of film, punching, shearing, welding, etc).

10

Million Meters

Profiles delivered annually in Italy

and the rest of Europe.

23

Lines of high productivity

Our company is spread over 7.000 sq.m. and has innovative extrusion machinery.

The choice of raw material

Choosing the best plastic raw materials for extrusion is crucial to ensure the quality and performance of the final product.

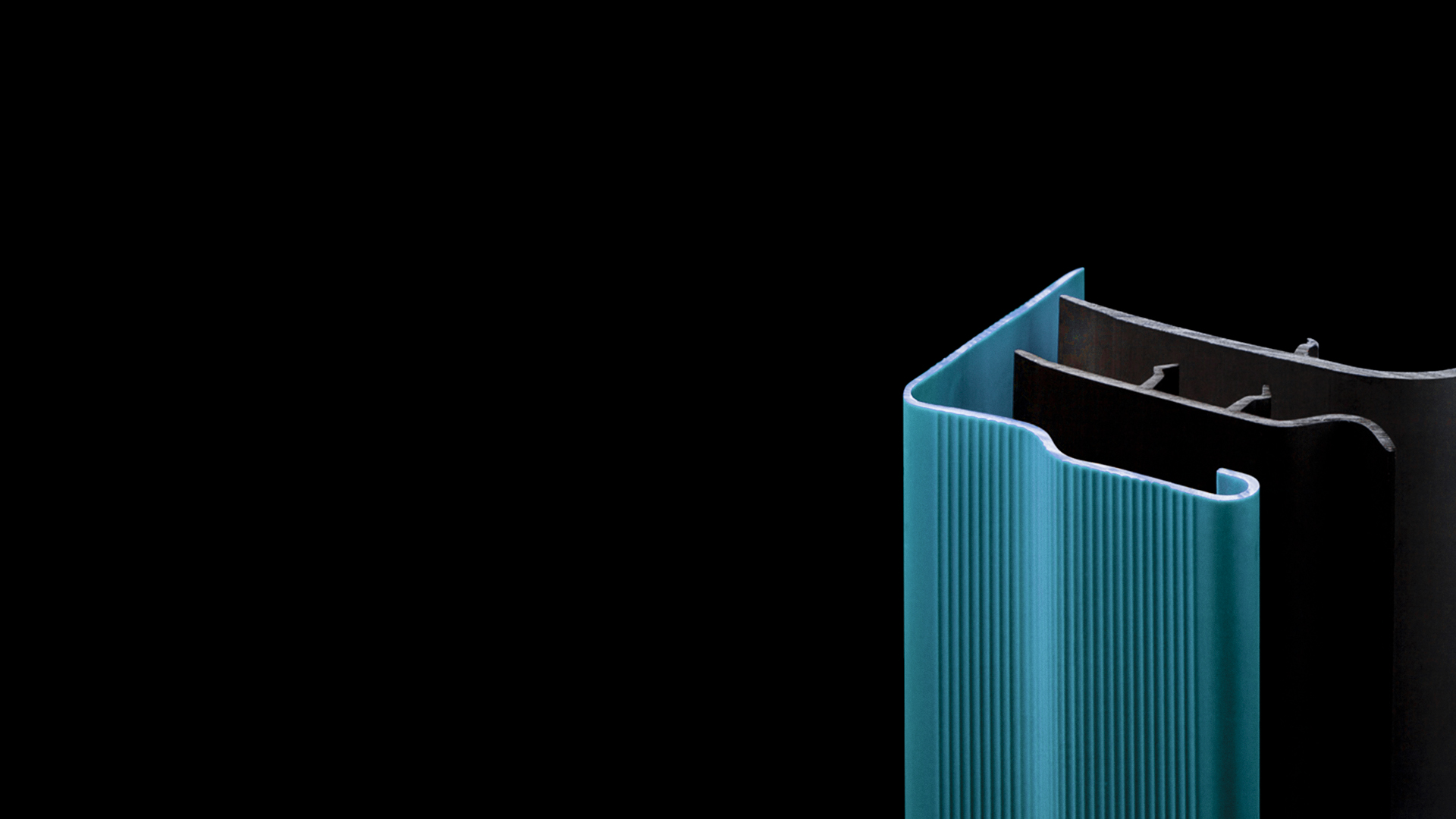

The extrusion

The plastic raw material into an extruder machine is melted and homogenized using heat and pressure. The molten plastic is then pushed through an extrusion head which gives it the desired shape.

The finished product

After which it is cooled and cut to the desired length. The plastic extrusion process is widely used for the production of plastic pipes, profiles, films and sheets.

Enjoy the process

These are the 5 stages of the process for creating a custom product for every business

We support you in your projects

Looking for help? Get in touch with us